富点设计中心 (FuDian design Center)

富点设计是“富”字公司下属内衣、泳衣、运动瑜珈、智能穿带和防护系产品的设计中心。

生产工厂成立于2002年。旗下有:布厂、织带厂、罩杯厂和内衣厂。

FuDian design is the design company for unerwear, swimwear, sports (yoga), functional clothes and protection products (We are a subsideiary of the "Fu" Group).

The manufactory was established in 2002. There are fabric manufactory、ribbon factory、bra pads manufactory and underwear factory.

生产工厂 (Manufactory)

成立于2002年,公司现有员工1000多人;工厂面积约4.5万多平方米,生产车间面积约2万平方米,先进生产设备800余台;工厂有各类技术人才约100余人,用先进电脑设计软件,多年以来我们致力于高质量内衣,胸杯生产,无痕女式内裤及文胸、织带等,产品远销世界各;工厂采用ISO9001 的质量管理体系及5S 现场 管理,严格控制产品质量,充分满足客户的各项要求。

Founded in 2002, the Co.has more than 1,000 employees. The area is more than 45,000 square meters, with a production workshop area of about 20,000 square meters and more than 800 advanced production equipment. The factory has more than 100 technical personnel of various types, using advanced computer design software, For many years, we have been committed to the production of high-quality bra cups, seamless women's underwear and bras, ribbons, etc., and our products are exported to all over the world. The factory adopts ISO9001 quality management system and 5S on-site management to strictly contro

织带和布料生产 (Ribbon & Fabric Factory)

自有布厂和带子厂,在新品开发,布料每月产量约120吨。带子每月产量是500万米。主要是做高端产品为主。对于质量和价格都很有优势

We have our own fabric mill and ribbon factory. In the new development , the output of fabric is about 120 tons per monthly and the output of ribbon is 5 million meters per monthly. Mainly

罩杯生产中心 (Bra Pads Factory)

3D SCAN技术及CNC 车床来开发模具及胶杯,产品开发准确快捷,能很好地满足客户高品质的要求。

3D SCAN technology and CNC to develop bra mould cup and plastic cups.The product development is accurate and high efficiency, which can well catch the high-quality requirements of customers.

工厂有产能为模杯500万对/月,布杯约200万对/月

The factory's current production capacity is 5 million pairs of bra mould cup / per month, and about 2 million pairs of fabric cup / per month.

样品生产中心(samples center)

**1000件以下的小单和所有样品将在设计中心完成。

The production will be completed in design center for all fit samples and the small orders (under 1000 pcs)

从纸样设计到样品裁剪全自动化,减少人手力度松紧造成尺寸差别。为后面大批量生产时标准化。同时也能满足小批量生产的成品下降,质量提升,能实现小单快返。

It is fully automated for sample cutting. It reduces the size difference caused by manual . It is standardized for subsequent mass production. At the same time, it can also meet the needs of small-batch production,improve quality, and achieve quick return for small orders.

车缝生产 (Sewing Line)

车缝生产在中国佛山和四川总产能是15万件/月,无痕文胸约15万件/ 月,无痕内裤约30万条/月(产品主要是内衣,泳衣,运动瑜珈和空调服);在孟加拉总产能是20万件/月,其中文胸12万件/月,内裤8万件/月。

Has a total capacity of 150,000 pieces /month and bonding bras are about 150,000 pieces/month, and bonding panties are about 300,000 pairs/month in Foshan and Sichuan in China (mainly underwear, swimsuits, sports yoga and functional clothing for air-conditioning ).In Bangladesh , there is a total capacity of 200,000 pieces, (of which 120,000 are bras and 80,000 are panties).

贴合生产 (Bonding)

贴合工艺生产于东莞,总产能是20万件/月(产品主要是塑身,文胸,内裤,泳衣)

The bonding is produced in Dongguan, with a total production capacity of 20K pieces/month ( mainly shapewear, bras,underwear, and swimsuits)

公司认证 Certificate

.

产品拥有欧盟“Oeko-Tex” Standard 100附录6环保证书及“REACH” 的各项测试。

l product quality and fully meet the various requirements of customers. The products have the EU Oeko-Tex Standard 100 Appendix 6 environmental protection certificate and various tests of "REACH"

合作品牌(Brand name)

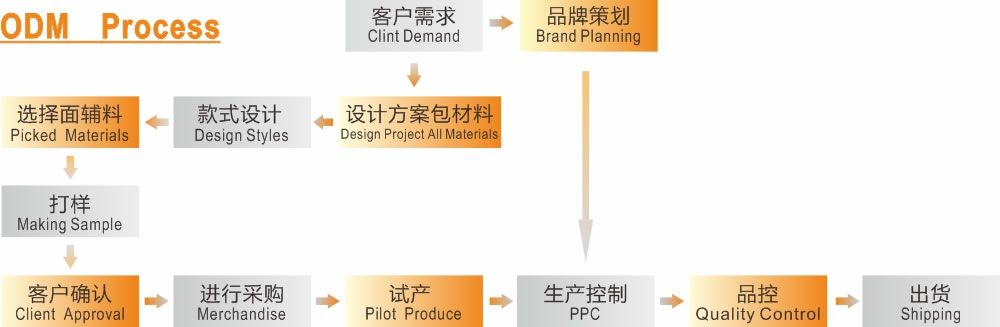

ODM

有强大的设计和技术团队,可以独立研发和设计产品的能力,另外,掌握成熟的供应链。

业务有包含产品开发、设计及生产。在接到委托后便会向品牌方确认需求,而后根据客户需求开发、设计产品,待产品终版确定后再进行量产,最后将产品交付给品牌方,由品牌方负责产品的推广与销售。为客户提供从设计到生产的全方位服务。

We have a strong design and technical team that can independently develop and design products. In addition, we have a mature supply chain.

The business includes product development, design and production. After receiving the project from client, we will be double confirmed what’s demand with the them, and then the product will be developed and designed according to the customer's needs. After the final version of the product is confirmed, mass production will be carried out. Finally, the product will be delivered to the client, who will be responsible for the promotion and sales of the product. Provide customers with the full services from design to production.